TPU film, as a high-performance polymer material, plays an important role in many fields due to its unique physical and chemical properties. This article will

delve into the composition materials, production processes, characteristics, and applications of TPU film, taking you on a journey to appreciate the technological charm of this material.

1. Composition materials of TPU film:

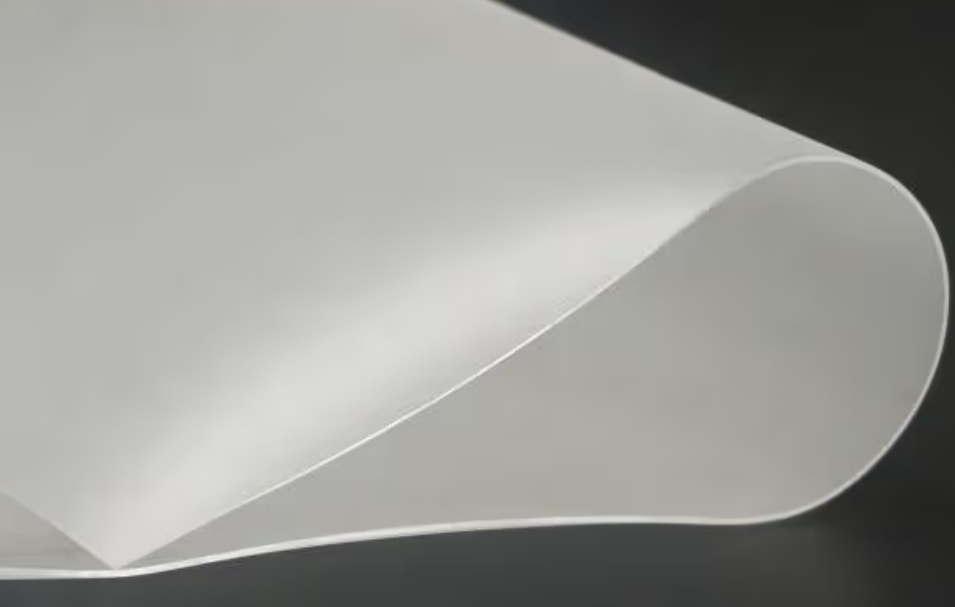

TPU film, also known as thermoplastic polyurethane film, is a thin film material made of polyurethane as the substrate through specific processing techniques. Polyurethane is a

polymer produced by the reaction of polyols and isocyanates, which has excellent wear resistance, elasticity, and chemical resistance. In order to improve its performance,

functional additives such as antioxidants and UV absorbers are also added during the manufacturing of TPU films.

2. Production process:

The production process of TPU film is fine and complex, mainly including the following steps:

Aggregation reaction: Firstly, under the action of a catalyst, polyols and isocyanates undergo polymerization reaction to form polyurethane prepolymers.

Melt extrusion: Heat the prepolymer to a molten state and then extrude it into a film through an extruder head.

Cooling and shaping: The extruded molten film is rapidly cooled by a cooling roller to solidify and form.

Post processing: including cutting, winding and other steps, to ultimately obtain the finished TPU film.

3. Characteristics:

The characteristics of TPU film are the basis for its wide application, mainly manifested in the following aspects:

High strength and elasticity: TPU film has high tensile strength and good elastic recovery ability, and can withstand large external forces without deformation.

Wear resistance: The surface hardness is moderate, with good wear resistance, suitable for various harsh environments.

Temperature resistance: able to maintain stability within the temperature range of -40 ℃ to 120 ℃.

Chemical resistance: It has good resistance to most chemicals and is not easily corroded.

Moisture permeability: It has a certain degree of moisture permeability and can be applied in situations where breathability is required.

4、 Application

Due to its excellent performance, TPU film has been widely used in various fields, including but not limited to:

Clothing industry: As a fabric for clothing, it provides a lightweight, waterproof, and breathable protective layer.

Medical field: Outer materials such as surgical gowns, protective clothing, etc. are used to make medical devices.

Sports equipment: used to manufacture sports shoes, bags, and other sports equipment, providing durability and comfort.

Automotive industry: As an interior decoration material, it can improve the comfort and aesthetics of the car environment.

Building field: used for roof materials, waterproof layers, etc., to improve the weather resistance and energy efficiency of buildings.

To sum up, as a multi-functional material, TPU film has been more and more widely used in modern society. Its composition materials are unique, production processes

are progressiveness, and product characteristics are diverse. TPU film, with its unique advantages, has demonstrated irreplaceable value in both daily life and high-tech fields.

Post time: Sep-26-2024