White, bright, simple, and pure, symbolizing purity.

Many people like white items, and consumer goods are often made in white. Usually, people who buy white items or wear white clothes will be careful not to let the white get any stains. But there is a lyric that says, “In this instant universe, refuse forever.” No matter how much effort you put into maintaining these items from being defiled, they will slowly turn yellow on their own. For a week, a year, or three years, you wear a headphone case to work every day, and the white shirt you haven’t worn in the wardrobe quietly turns yellow on your own.

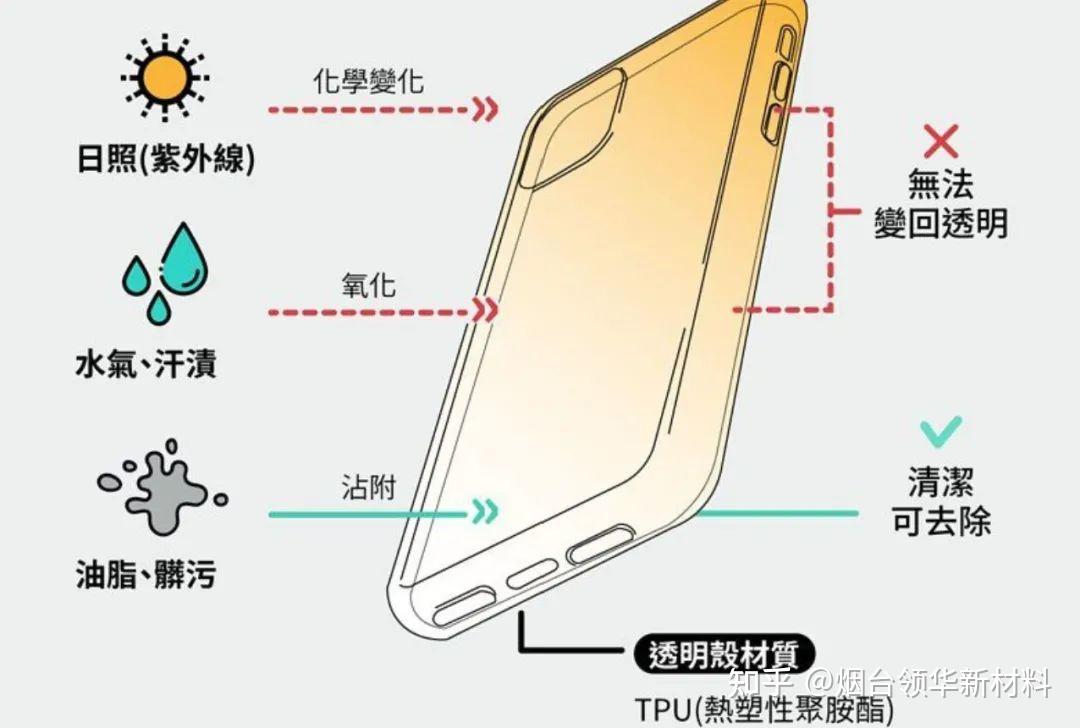

In fact, yellowing of clothing fibers, elastic shoe soles, and plastic headphone boxes is a manifestation of polymer aging, known as yellowing. Yellowing refers to the phenomenon of degradation, rearrangement, or cross-linking in the molecules of polymer products during use, caused by heat, light radiation, oxidation, and other factors, resulting in the formation of some colored functional groups.

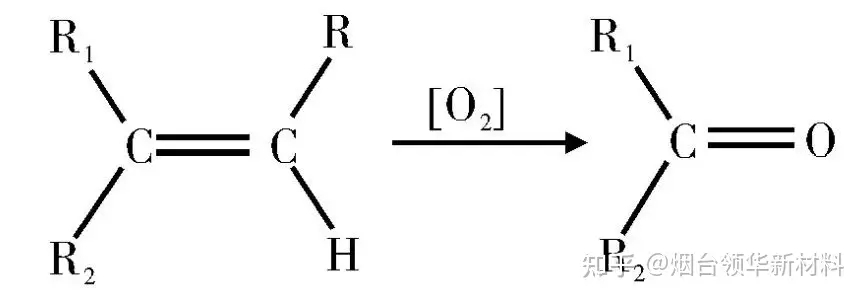

These colored groups are usually carbon carbon double bonds (C=C), carbonyl groups (C=O), imine groups (C=N), and so on. When the number of conjugated carbon carbon double bonds reaches 7-8, they often appear yellow. Usually, when you notice that polymer products are starting to turn yellow, the rate of yellowing tends to increase. This is because the degradation of polymers is a chain reaction, and once the degradation process begins, the breakdown of molecular chains is like a domino, with each unit falling off one by one.

There are many ways to keep the material white. Adding titanium dioxide and fluorescent whitening agents can effectively enhance the whitening effect of the material, but it cannot prevent the material from yellowing. To slow down the yellowing of polymers, light stabilizers, light absorbers, quenching agents, etc. can be added. These types of additives can absorb the energy carried by ultraviolet light in sunlight, bringing the polymer back to a stable state. And anti thermal oxidants can capture the free radicals generated by oxidation, or block the degradation of polymer chains to terminate the chain reaction of polymer chain degradation. Materials have a lifespan, and additives also have a lifespan. Although additives can effectively slow down the rate of polymer yellowing, they themselves will gradually fail during use.

In addition to adding additives, it is also possible to prevent polymer yellowing from other aspects. For example, to reduce the use of materials in high temperature and bright outdoor environments, it is necessary to apply a light absorbing coating to the materials when using them outdoors. Yellowing not only affects the appearance, but also serves as a signal of material mechanical performance degradation or failure! When building materials undergo yellowing, new substitutes should be replaced as soon as possible.

Post time: Dec-20-2023